Hydrogen’s role in net zero

Hydrogen is a crucial part of delivering net zero in the downstream sector. It has an important role to play in replacing refinery fuel gas (RFG) as a source of energy in refineries. In addition, it can be sold to power airplanes or vehicles on the ground, or for heating in the UK.

Fuels Industry UK is working with stakeholders to ensure the downstream sector has a key role in the future production, distribution and use of low carbon hydrogen in the UK. Refineries are the largest producers and consumers of hydrogen in the world and UK-based refiners have been working safely with hydrogen for over 60 years.

Rationale for Hydrogen

The importance of low carbon hydrogen in meeting net zero by 2050 is clear from the Climate Change Committee's (CCC) report to Parliament: in it we see that hydrogen may have a role in the decarbonisation of various sectors including industry, buildings, and transport, even making mention of the involvement in hydrogen production for Greenhouse Gas (GHG) removals.

How low carbon hydrogen can be made

Hydrogen is not itself an energy source and must be produced using other sources of energy, such as wind or nuclear generated electricity used to split water via electrolysis or from the conversion of hydrocarbon sources (gas reforming). Where the source is from fossil resources, then no carbon benefit is gained unless the carbon is captured such that CO2 is not released to the atmosphere, a process called Carbon Capture Utilisation & Storage (CCUS). Where the source is biogenic, then conversion to hydrogen with CCUS is a mechanism to remove carbon from the biosphere, known as Bio-Energy Carbon Capture & Storage (BECCS), a form of geoengineering.

For more information on hydrogen production see our Factsheet in the links at the bottom of this page (or in publications).

Ongoing Projects

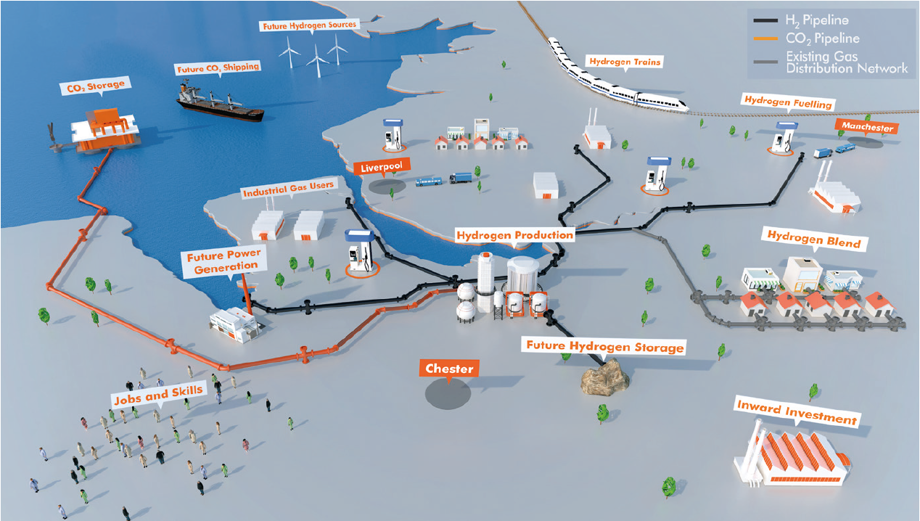

HyNet Low Carbon Hydrogen project involves the development and deployment of a 100kNm3/hr hydrogen production and supply facility

Source: Cadent

The project is focussed on decarbonising refinery hydrogen production, but may develop further through the following options:

- Decarbonisation of heat in industrial clusters with creation of localised hydrogen markets

- Supply of hydrogen for road transport or aviation use

- Supply of hydrogen for decarbonisation of gas networks

Hydrogen production via electrolysis also provides a new option for energy storage and electricity supply management. During periods of lower electricity demand, surplus generation capacity could be used to produce hydrogen for storage to be released into gas networks or for road transport use when required, providing additional flexibility in the energy system. Creating electrofuels (e-fuels) from stored hydrogen may also make sense where losses incurred in production are offset by efficiencies gained in infrastructure and fuel quality.

How hydrogen will be used

The UK with a large gas grid, may be uniquely able to harness hydrogen’s potential for decarbonisation by upgrading existing infrastructure (pipelines and boilers) rather than having to create an entirely new hydrogen transport and transmission system. As with electrification of the power grid through renewables, there is potential for decarbonising the gas supplied via the National Transmission System (NTS) and gas networks if hydrogen is blended into natural gas (NG).

The Great Britain (GB) grid could be blended with up to 20% hydrogen, according to the Department of Energy and Net Zero (DESNZ) and the Energy Networks Association estimates that a 20% hydrogen blend in the gas grid would save around 6 million mt/year of CO2 with CO2 savings amount to a reduction of around 6%-7%. Replacement of Natural Gas (NG) by hydrogen is being considered under the Energy Networks Association “Gas Goes Green” project.

How high blends or 100% hydrogen will be distributed

Today, most hydrogen used is produced at or close to where it is used, typically at large industrial sites, and the infrastructure needed for distributing hydrogen (above 20%) still largely needs to be developed in the UK.

Currently, pure hydrogen may be distributed through three methods.

Pipeline: This is the least-expensive way to deliver large volumes of hydrogen but the capacity is currently limited in the UK, outside of large industrial complexes, with approximately 40km of pipeline.

Cadent are working with HyNet on an industrial hydrogen pipeline distribution system in the North-West[1]. National Grid are studying the potential for a 2000 km hydrogen pipeline system in the UK[2], which will link industrial sites in the first instance.

High-Pressure Tube (HPT): Hydrogen is typically transported in tube trailers in the UK. A typical trailer would be filled to 228 bar and would carry around 300 kg of hydrogen. High-capacity trailers are now available on the market, which could carry 600 kg at 228 bar and 900 kg at 300 bar. There are also 500 bar trailers in development.

Liquefied Hydrogen (LH2) tankers: Cryogenic liquefaction is a process that cools hydrogen to a temperature where it becomes a liquid. Although the liquefaction process is expensive, it enables hydrogen to be transported more efficiently (compared with high-pressure tube trailers) over longer distances by truck, railcar, ship, or barge.

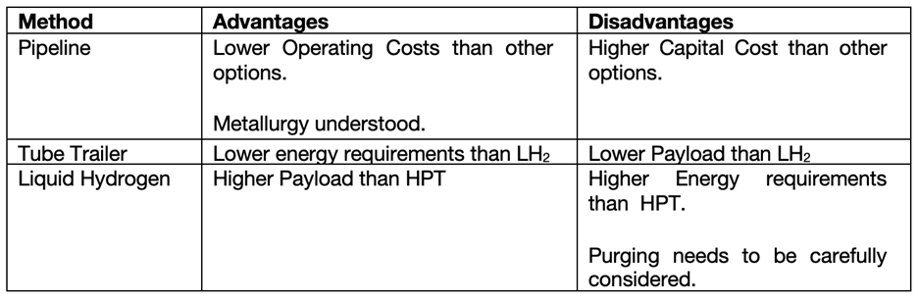

Advantages and Disadvantages of Distribution Methods for high blend Hydrogen

The table below summarises some of the key advantages and disadvantages

[1] https://cadentgas.com/news-media/news/june-2021/hynet-north-west-%E2%80%93-leading-a-green-recovery

[2] https://pgjonline.com/news/2021/may/national-grid-studying-uk-hydrogen-pipeline-network-potential